Vurcon VL-127 machining center

- Made to order

- CNC Customization

- National technical support

- 24-month warranty

Fast Shipping

Quality Guaranteed

Customized quote

Secure Payment

Ref.: VL-127

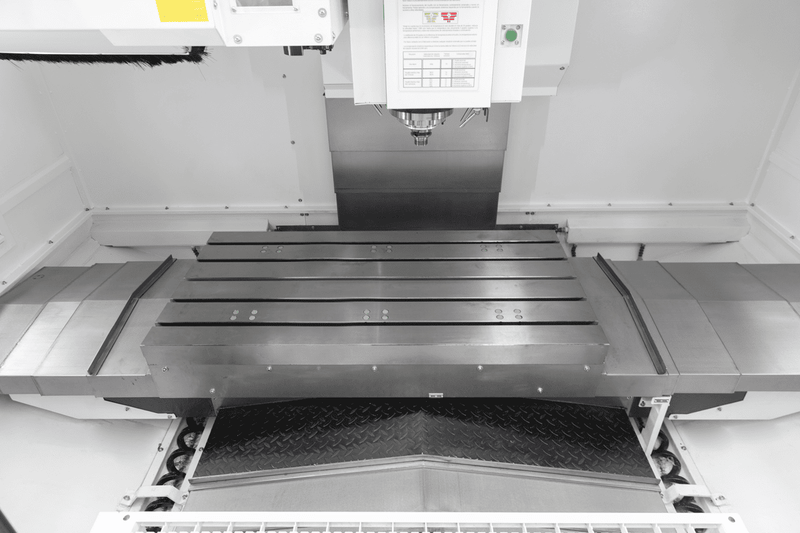

| Worktable (WxL) | 700x1400 |

| X/Y/Z axis travels | 1200/700/700 |

| Speed range |

20 - 10000 |

Standard configuration

- CN Fanuc 0i-MF PLUS (Type II)

- 15” TFT color touch screen

- Manual Guide i

- Rigid Tapping

- Communication Interface: Ethernet, USB, CompactFlash, RS232

- Main motor of 15 kW, with a Torque of 191Nm.

- 3kW Axis Servomotors.

- 10,000 RPM

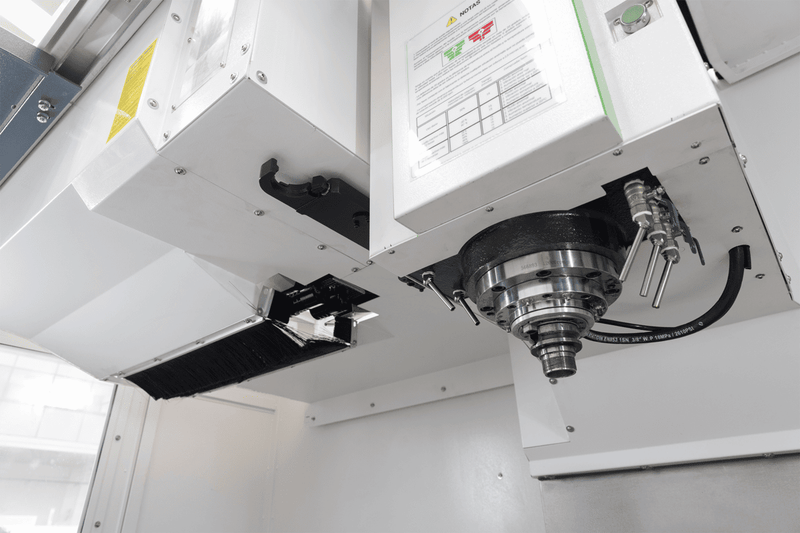

- Head cooled by oil cooler

- BBT-40 Taper

- 24-position double-arm tool changer with Random exchange

- Oil/coolant separator

- Chain-type chip extractor, with two side screws + trolley

- Linear guides with roller carriages on all three axes

- Telescopic protections on all three axes

- Automatic lubrication

- Air conditioning in the electrical cabinet

- Circular cooling system in the main spindle plus coolant nozzles

- Chip sweeping by coolant jet

- Coolant through the tool with high-pressure pump of 20 Bar + Subtank with filters

- Work light and machine status light

- Automatic disconnection (M30 Off)

- Full enclosure

- CE Marking

Designed for your workshop

Endless configuration options for every project

Feature

Head transmission type

Electrospindle

Gearbox

Straps

Direct drive motor

Feature

Controls

HEIDENHAIN

FANUC

SIEMENS

FAGOR

Feature

Printhead speed (rpm)

6000 RPM

8000 RPM

10000-12000 RPM

12000-15000 RPM

Siemens 828D Control

Cone type

BT40

BBT40

BT50

BBT50

Feature

Renishaw tool measuring probes

Contact probe

Laser Probe

Feature

Tool changer

Drum type (30,32)

Chain type (32/40/60)

Feature

OPTIONAL: Optical scales on the (XYZ) axes

Optical scales on the (XYZ) axes

Industrial protection

Rotating Table

4th axis with manual tailstock

4th axis with cradle tailstock

4th and 5th axes

Industrial protection

Chip evacuator

Chain

Scratcher

Endless screw

With cutting fluid filter drum

Industrial protection

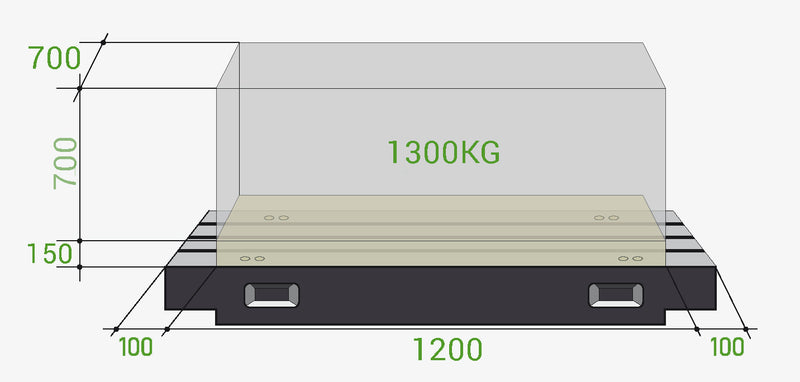

Travels on the X/Y/Z axes

Select the model according to the routes required for your application:

| Model | X-axis (mm) | Y-axis (mm) | Z-axis (mm) |

|---|---|---|---|

| VL-65 | 650 | 400 | 500 |

| VL-85 | 850 | 500 | 550 |

| VL-106 | 1000 | 620 | 630 |

| VL-116 | 1100 | 650 | 600 |

| VL-127 | 1200 | 700 | 700 |

| VL-147 | 1400 | 700 | 700 |

| VL-157 | 1500 | 700 | 700 |

| VL-158 | 1500 | 800 | 800 |

| VL-178 | 1700 | 800 | 800 |

💡 Tip: Choose the model based on the maximum size of the workpiece you will be machining. Consider adding a 10-15% safety margin to your current requirements.