Before purchasing a lathe, it is necessary to do prior research to define the type of lathe you need, since this type of machine can be found on the market in a wide variety of models, each with specific characteristics.

Depending on what tasks are planned to be carried out, it may be more advisable to use one type of lathe or another . This is an important investment in machining tools, so it is also crucial to have a precise idea of what characteristics the most suitable lathe will have.

In the event that the investment is made by a company, as is common in relation to industrial lathes, the lathe will become part of the assets of said company, so it must also be analyzed whether the lathe will be capable to allow the investment to be recovered . Aspects such as the usefulness and longevity of the machine are the most related to the profitability it will offer.

Keys to buying the correct lathe

Before purchasing a lathe, it is necessary to define three key aspects: how many pieces are planned to be worked with the machine and in how much time, what operations are planned to be carried out with the machine and what will be the amortization period for the investment .

When you plan to work with a large number of pieces in a short time and perform specific operations, it is best to invest in a high-end lathe. For its part, when the payback period is not very long and you do not plan to carry out too many operations, you can consider the option of purchasing a medium or low-range lathe or even a used one .

Features to consider when purchasing a lathe

There are certain specific characteristics that must be taken into account when it comes to the type of lathe you are going to purchase. These are the following:

Engine power

The easiest way to differentiate the range of a lathe is through the power of the main motor. Lathes with a 350W motor power are the only ones considered suitable for professional operations. Motors with lower power levels are not recommended for the most demanding tasks.

On the other hand, when evaluating an engine, the maximum permitted external diameter must be analyzed. This aspect is directly related to the size of the pieces to be worked on . If you plan to work with small pieces, it is not such an important aspect; But, when it comes to large pieces, it is essential that it allows a wide maximum diameter.

Diameter on carriage and on bed

In addition to the maximum diameter allowed by the motor, the diameter on the carriage and on the bed indicated in the machine's technical sheet must be taken into consideration. When the maximum diameter allowed by the bed is not very wide, the plate can be placed, but the operations to be performed are limited. Therefore, a bed diameter appropriate to the operations planned to be performed must be selected.

This is especially important when the part must be completely cylindered, since in this case it could be impossible to do so because there are two aspects that also affect the work space :

- The thickness of the sliding carriage.

- The space occupied by the turret where the cutting tool is added.

Distance between points

The distance between points must be appropriate according to the length and type of pieces to be worked . This distance is measured between the tailstock and the platen.

In addition, the supports that the lathe has must also be considered, since there are mobile steady rests and fixed steady rests. Depending on the pieces to be worked, mobile or fixed steady rests may be more convenient.

Automatic settings

When purchasing a lathe, you should evaluate whether you want to have automatic adjustment of feed speed and revolutions . Depending on the planned production control, these functions may or may not be necessary. Furthermore, when a lathe lacks these automated systems , the work cannot be carried out continuously without resorting to stopping .

Likewise, it significantly facilitates the modification of the rotation speeds of the main spindle. When it is easy to work at different speeds, work efficiency is improved .

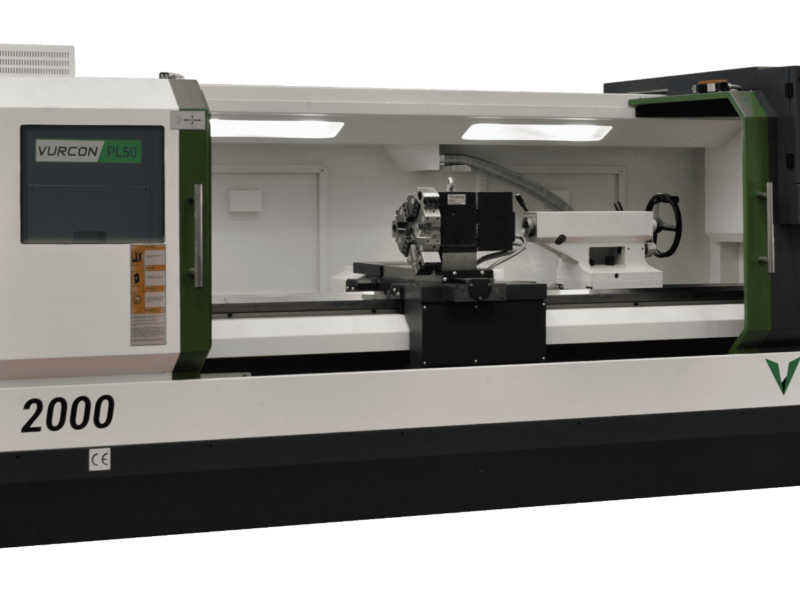

Buy CNC or conventional lathe?

At a technological level, there is the possibility of acquiring a conventional lathe or one with numerical control. To define which is the best option, you must take into account what the work cycles are like in the company and the level of precision required by the pieces to be worked on . If you do not have too many personnel and the level of precision required is very high, the best option is a CNC lathe . Otherwise, a conventional lathe is a good choice.