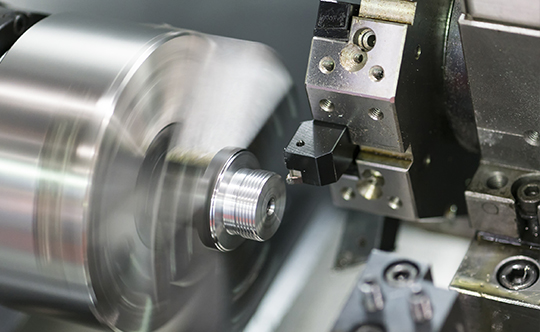

In the modern manufacturing industry, choosing the right equipment is crucial to ensuring efficiency, precision and profitability . CNC (Computer Numerical Control) metal lathes are a significant investment for any workshop or factory, and selecting the most appropriate one can be a challenging task. This article provides a detailed guide on the essential attributes and factors you should consider before making your purchase.

Machining Capacity and Size

First of all, determine the maximum dimensions of the parts you plan to machine. CNC lathes come in a variety of sizes, and you'll need one that can accommodate the size and volume of your production without sacrificing precision. In addition to all this, it is interesting to request a part interference drawing from the manufacturer to guarantee that the parts or range of part measurements that we want to produce can be made on that CNC Lathe .

Spindle Power and Speed

Spindle power and speed are crucial to cutting efficiency and finish quality. A spindle that offers a range of speeds will allow you to work with a variety of materials and make precise cuts at different depths and dimensions. The cutting conditions and the play a fundamental role.

CNC control system

The brain of a CNC lathe is its control system. Look for systems that are intuitive and compatible with industry-standard programming software. Ease of use can significantly reduce the learning curve and increase productivity.

In the case of Vurcon , Siemens, Fagor and Fanuc are installed, and they all have an intuitive conversational system for programming parts.

Tools and accessories

The versatility of a CNC lathe often depends on the tools and accessories available. Evaluate the quality and variety of tools and options that come with the lathe, as well as their availability for future expansion or replacement. Elements such as C axis, Y axis and motorized tool must be selected before purchasing, since in most cases they cannot be installed later.

Sturdiness

Robust construction is vital for continuous and accurate operation. A CNC lathe must be able to withstand the vibrations and stress of machining without compromising the integrity of the workpiece. Our machines have great weight that provides great robustness during the machining of metal parts. Optimal cutting conditions must always be taken into account.

Technical service

Good customer service and technical support can be as important as the machine itself. Investigate the manufacturer's reputation for spare parts availability and responsiveness of technical support.

In the case of Vurcon has spare parts for all its machines, with more than 15 years since the sale of the model in question. On the other hand, most of the components of Vurcon machines are standard, from the Hiwin roller skate guides to the THK spindles, it is easy to find such elements at common machine component suppliers.

Total expense including maintenance

Beyond the purchase price, consider the total cost of ownership, which includes maintenance, repairs and energy consumption. A cheap CNC lathe could be more expensive in the long run if it is expensive and frequent to maintain. Therefore, it is interesting to carry out preventive maintenance to avoid costly repairs, guaranteeing the durability of the CNC lathe and quality.

Selecting a CNC metal lathe requires careful consideration of several technical and service factors. By considering machining capacity, spindle power and speed, control system, tools and accessories, construction and stability, technical support, and total cost of ownership, you can make an informed decision that meets your needs. production and budget. With the right choice, your investment in a CNC lathe will significantly improve the efficiency and quality of your metal work.

At Vurcon it always offers a quality product, with quality components, along with great equipment, so that the part you want to turn is the only thing you have to worry about. Discover the entire range of Vurcon CNC metal lathes , which includes both parallel lathes and inclined bed lathes .