The CNC lathe is a machine tool that, through the machining process, produces pieces of revolution such as screws, axles, threaded rods, pins and much more. The acronym CNC stands for Computerized Numerical Control , so the settings are defined using a specialized software program, usually with a license that enables its use. The computer controls a series of alphanumeric data that the machine applies to manufacture a specific part in quantities.

CNC lathes represent an advance in turning, since all the work that was previously carried out by parallel, vertical, automatic and copy lathes is now carried out by a single machine. From semi-finished products, such as billets or ingots whose materials can be copper, stainless steel, aluminum or magnesium, among others, the CNC lathe makes the indicated pieces with the measurements that you want to provide.

The computerized application represents the latest technological advance in a machine, the lathe, which has been present for a long time in industrial manufacturing processes. In fact, at the beginning of the industrial revolution the first prototypes of lathes can already be found.

How does a CNC lathe work?

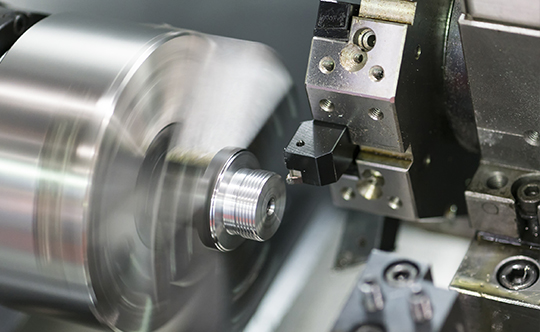

The CNC lathe works from Cartesian X and Z axes , and the machining process. This process consists of the shaping of parts from abrasion or chip removal . With a material of a certain size, CNC lathes work these materials until obtaining the desired part.

First, the prefabricated part is placed in the tool holder compartment, and it begins to rotate when the program starts. The X and Z axes move according to the parameters previously defined in the computer and in this way the part is molded. All the pieces that come out will have an identical finish, with the same dimensions and measurements.

Using software programs such as BobCAD-CAM or AlphaCAM, among others, you will be able to model the part you want to obtain in great detail. These programs include all types of configuration features , in addition to the preview of the part in question. The most advanced CNC lathe software even shows you the production simulation, that is, they show you how the lathe will work until the product is ready. Once you have the parameters defined in the program, you enter the data into the CNC lathe, and place the material to work on. The machine takes care of the rest.

Advantages of CNC lathes

CNC lathes have a number of advantages over traditional lathes . They are high-cost machinery , so it involves a real investment. However, the investment is profitable with benefits in the medium and long term, since these industrial tools more than cover the deficiencies of mechanical lathes, or manual work.

- The pieces of revolution obtained by machining are of high precision. In some cases the precision is nanometer.

- Changing the configuration for the production of a different part is done quickly.

- It can produce highly complex parts quickly and efficiently.

- Production times are reduced, so more pieces can be produced in the same period of time.

- Errors derived from manufacturing are reduced. If there are any, they can be easily detected and corrected in the software program.

- Likewise, human errors are reduced.

- In the long term it means a reduction in costs and there is increasingly more efficient and cheaper machinery.

Types of CNC lathes

There are three types of CNC lathes . On the one hand we have the flat bed CNC lathe , which, depending on the subtype, will be used to manufacture either small pieces or medium or large pieces. They are the most used since their applications are varied and they allow all types of parts to be manufactured using a refrigeration system.

Then there are the vertical CNC lathes , more suitable for large and massive parts and which work with the aforementioned X and Z axes. It is a very useful type of lathe for producing automotive parts, such as engine blocks. inclined bed CNC lathes , which are the most sophisticated in terms of control and digital operation. Likewise, they are among those that offer greater precision and rigidity in the finishing of the pieces. They carry out drilling, milling and turning tasks, and are suitable for both small and large parts.