Polyvinyl chloride, better known as PVC, is a type of plastic widely used due to its low cost, but also for its multiple applications. This plastic has the characteristic of not degrading under the action of sunlight, in addition to being incredibly resistant to water and wind. But, how is PVC machining done?

The benefits of PVC for the industry

Polyvinyl chloride is a plastic derivative that originates due to the polymerization of vinyl chloride monomer when it is transformed into polyvinyl chloride. To obtain this polymer, two peculiar elements are required: sodium chloride or natural salt and oil or natural gas and it is obtained by following any of the four production processes that exist to create it: emulsion, suspension, mass and solution.

Among its physical characteristics we find that PVC is white, amorphous and opaque; It softens at 80 °C and, to decompose, requires the temperature to rise to 140 °C. Thanks to its physical characteristics, PVC machining is very simple and economical.

PVC is one of the most used plastics in the world, particularly due to its low cost, and since its production, this plastic is very economical when compared to others. During the production processes, the physical and chemical characteristics of PVC are maintained, which makes it a very versatile material capable of being adapted to multiple areas and tasks. For example, it is very common to find it in construction, but also in food preservation, among many others.

PVC characteristics

To begin with, PVC is a plastic that is very resistant to the environment, fire, and even has excellent electrical resistance, which is why it is widely used to make electrical connections and installations. Another characteristic of PVC is that it can change its shape if the appropriate pressure is applied (it is ductile), but it also has a lot of toughness; toughness refers to a property of materials; This is the total strain energy that a material can withstand before breaking. PVC can resist up to 60 years! Furthermore, this plastic is stable.

Types of PVC

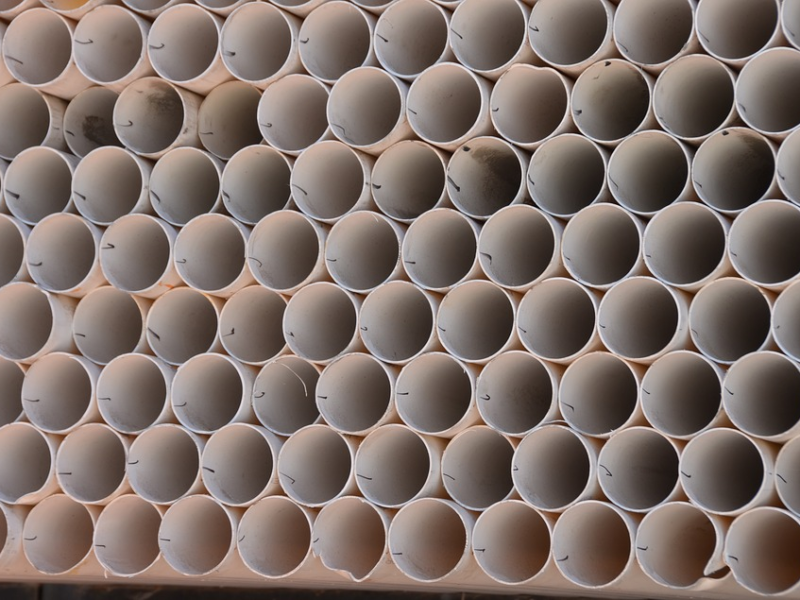

Due to its resistance, PVC is divided into two: rigid (PVC-U) and soft (PVC-P). Rigid PVC is the one most used to come into contact with pipes, for example; since it is not corrosive. Soft PVC is most commonly found protecting cables.

Processes for PVC machining

Plastics have a lower thermal conductivity than metals, which is why it is essential to disperse the heat generated during machining. And as we have already mentioned, PVC requires high temperatures to begin to deform and, when these temperatures rise to more than 200 °C, toxic and harmful substances may be produced.

When you want to machine PVC, the most common thing is to use one of these processes:

- Injection molding: In which a molten polymer, ceramic, or metal is injected into a cold, snap-close mold. The injection is made through a small hole or gate.

- Extrusion: Molding is performed using a continuous flow of pressure and thrust. The plastic passes through a mold that gives it shape.

- Pressing: Plastic pressing molding is one in which the plastic is poured into a mold that is closed, with another mold on top of it and to which heat and pressure are applied.

- Lamination, resin mixed with a catalyst or hardener is used and a mold is wet with this mixture. The goal of this method is to use a reinforced piece.

CNC machining

For PVC machining it is possible to use the vast majority of machine tools used to machine metals and wood, but they must have a ground tool to use on plastic. The speed must be controlled and be lower than when machining metals; In addition, the feed speed must be high and lack cutting depth. To disperse the heat correctly, it is possible to use water or compressed air; With this, it is possible to carry out the cooling procedures after machining.

One of the most used machine tools for PVC machining is the numerical control milling machine . This milling machine allows you to remove chips, but also perform many other jobs such as flattening, slotting, drilling, threading , etc. Thanks to the programs that the milling machine's computer works with, it will be possible to choose the type of work you want to do on the piece and indicate that the material to be worked on is plastic; It is also possible to program and adjust the speed of the cutter, which is the cutting tool of this machine.