A vertical machining center is an automated industrial machine that is used to carry out various types of machining through the installation of Computer Numerical Control ( CNC ), which requires minimal human intervention, with manual handling.

This machinery is generally used to cut, shape or machine metals, plastics, wood , among other materials . With this mechanism, industrial production capacity is increased at higher speeds.

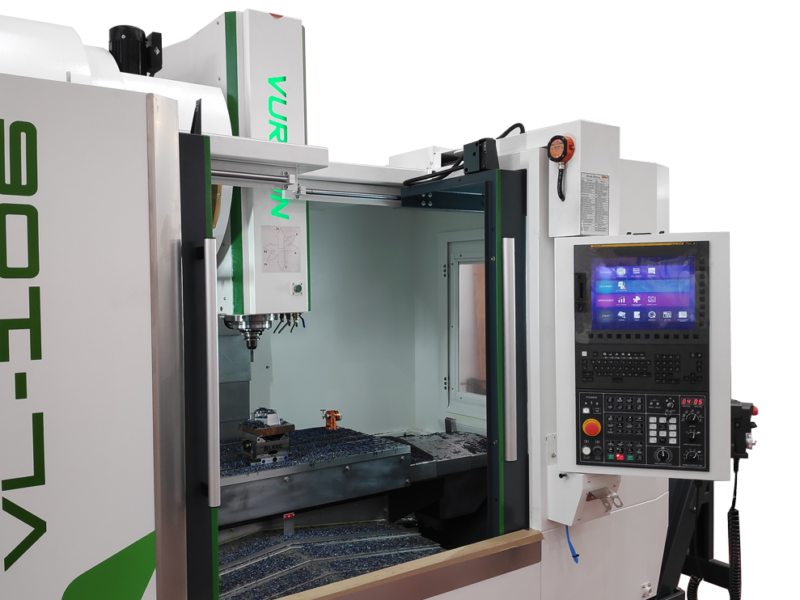

There are machining centers of various sizes and for different purposes, although all are equipped with a rotating head that works from the top of the material to the bottom, making cuts, by rotation, to the worked piece . With this machine you can get quality, reliable and very functional parts, as it is characterized by being a very precise tool.

When do we need a vertical machining center?

The types of services provided by a vertical machining center are required by companies that need a tool that makes rotary cuts, among them we can mention:

- Manufacturing industry : manufacturing of injection molds, matrices, parts, etc.

- Automotive : manufacturing of parts and complete pieces of the interior and exterior of the engine , such as blocks, carburetors or molds and matrices for bodywork and accessories.

- Electronics : parts for prototype printed circuits.

- Aeronautics : Production of parts and components for airplanes or drones, among others. It includes both structural aircraft parts and fuselage, flaps and other elements.

- Aerospace : Machining of all types of special alloys for satellites , rockets, and other types of aircraft. From Inconel to titanium alloys can be machined with CNC machining centers.

- Medical and dental industry: manufacturing of orthopedic parts for various specialties, including: stainless turning, closures, dental implants, prostheses, crowns, bar turning parts for the machines and tools used by dentists.

- Energetic : high precision machined parts for windmills.

- Appliances : manufacturing of industrial parts for the repair of discontinued household and industrial appliances , since it is very difficult to obtain original parts.

- Hardware : manufacturing of pieces for personalized or industrial furniture . Hardware components of various sizes, as well as elements for metal doors, frames, among others.

- Textile industry : production of various pieces: zippers, buckles, buttons, buttons , as well as specific cuts are made in soles, belts and special shapes are made in earrings.

- Construction : making closures, frames and windows, parts of a door, among others.

- Lighting : turning to manufacture decorative and functional elements for lamps, fastenings and urban planning lighting.

There are countless sectors that need these vertical machining centers to produce functional parts for their business. Only one drawing is required to manufacture any type of part.

Characteristics of vertical machining centers

- They are very versatile and flexible machines with a high degree of automation, which makes them ideal for carrying out several machining operations on a single piece.

- They have the ability to change their configuration quickly and work on various tasks with the same part.

- They can perform milling , as well as high-precision drilling and tapping functions.

- They offer an excellent surface finish to the pieces that are manufactured , ideal for giving their final shape.

- They are ideal for mass production , thanks to the uniformity they provide in production.

- They have a high manufacturing speed , because they can carry out many operations automatically on each piece that is worked.

Advantages of vertical machining center

Vertical spindle machining centers have a rotating head and generally work on the top of the part . This type of machinery provides great rigidity and manufactures parts with excellent dimensional precision. In addition, it has a series of advantages:

- It is an excellent cooling system that provides stability to the piece by regulating the temperature.

- Time savings thanks to automatic tool change.

- Reduction of accidents , since human participation is minimal.

- It does not require much training for those who operate it .

- The machine can perform various operations at the same time .

- It can operate 24 hours a day .

- There is no need to make prototypes because there is software that simulates the production of the design prior to actual manufacturing.

- High process precision .

- Can perform complex processes .

On the market there is a wide variety of models of mechanized centers that offer the possibility of carrying out work on small and large pieces regardless of the quantity.

This type of machines help to find solutions adapted to each sector in a reliable and safe way. Find the one that best suits your needs and enjoy unmatched production.

Other types of machining

In addition to the vertical machining center, there are other types that are distinguished from each other according to their functionality, degrees of automation and size.

Machining centers with horizontal spindle

They are used to work with tall and large pieces , which need to be machined in various parts.

Machining with chip removal

It has a cutting tool that produces metal chips . It is ideal for performing roughing processes with the aim of quickly removing a vast amount of material.

Machining without chip removal

It is used to transform any piece, regardless of its complexity.

Abrasion machining

It consists of eliminating the material due to wear of the piece . This process requires less force to get rid of materials, however, it is slower than other types of machining.