Introduction to CNC machining

Introduction to 3-axis CNC machining

When it comes to precision machining, the 3-axis machining center is a powerful tool that can revolutionize your manufacturing process. This cutting-edge technology offers unparalleled versatility, efficiency, and precision, making it essential for any machining professional.

In essence, a 3-axis machining center is a computer-controlled machine tool that uses three axes of movement (X, Y, and Z) to perform a wide range of machining operations. This means the machine can move in three directions simultaneously, allowing it to cut, drill, mill, and shape materials with precise and complex chip removal.

One of the key advantages of a 3-axis machining center is its ability to handle a variety of workpiece sizes and shapes. Whether you are working on small, intricate components or large-scale projects, the machine's versatile design can easily accommodate different sizes and geometries.

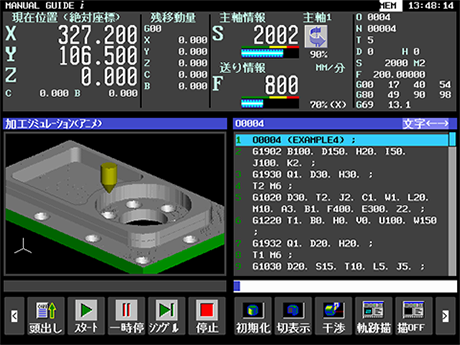

Additionally, the advanced automation features of a 3-axis machining center streamline the manufacturing process, reducing manual work and increasing productivity. With computer numerical control (CNC) capabilities, operators can program the machine to execute complex machining operations with high precision and repeatability.

The precise control and accuracy offered by a 3-axis machining center are particularly beneficial when working with tight tolerances and demanding specifications. The machine's smooth and controlled movements ensure consistent results, minimize errors and rework, and ultimately save time and resources.

In addition to its technical capabilities, the 3-axis machining center also offers a user-friendly interface, allowing operators to easily program, monitor, and control the machining process. This enables machinists to unleash their creativity and expertise, pushing the boundaries of what is possible in terms of design and manufacturing. Depending on the brand of the control, there are different conversational systems for programming the part to be made, in addition to ISO programming or G-code, universally known and taught in vocational schools related to CNC and mechatronics. Some of the most well-known conversational software for on-site machine programming are:

In conclusion, the 3-axis machining center represents a turning point in the world of machining. Its versatility, precision, and automation capabilities make it an essential tool for any manufacturing operation. Whether you are an experienced professional or new to the industry, mastering this powerful machine will open up a world of possibilities and elevate your machining skills to new heights.