Lathes

INDUSTRIAL LATHES

Industrial lathes are some of the most used machine tools in the metalworking industry. These equipment are used in most industrial processes, in which metals or other materials are machined in order to obtain endless pieces or shapes as a result.

The value of lathes lies in their multifunctionality, the ability to optimize production and the redirection of human capital in the industry. Industrial lathes are machinery that stands out for its structure, its recognized versatility and its practical implementation.

Main structure of an industrial lathe

Although industrial lathes can have a horizontal or vertical axis or operate by numerical control (CNC lathes), in general they all have the same components, which vary little from model to model. Some of those essential elements are described below:

- Bench: is the structure used as support for the lathe. On top of it rest other pieces that make up the team and are essential for its performance. They are capable of dissipating the vibrations emitted during the machining process, although, sometimes, this task is facilitated by some accessories.

- Norton box: it is made up of several pieces, among which the pulleys, gears and belts stand out. Thanks to the union of these elements, adjustments can be made in the speed of rotation, using external levers that the operator manipulates according to his needs. This box makes it possible for the lathe movement to be automatic.

- Fixed head: it is the part of the lathe that is responsible for holding the material to be machined. In addition, this component is responsible for rotating the base work piece during the machining process.

- Moving headstock: these heads can be moved manually or automatically across the surface of the lathe bed, thanks to the guides in which they are held and the push of the operator or action of the machine tool. Eventually, it is used to fix or hold large and large pieces. If you want to fix the moving head, it has a lever or electronic mechanism to do so.

- Tool carts: as their name indicates, they are carts that transport the different work tools that are implemented in the mechanization process. These cars have greater independence with respect to the movements they can make through the available guides and mechanisms.

General operation of the lathe in the industry

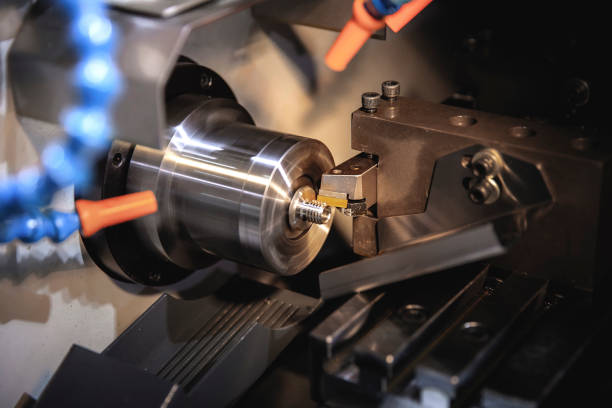

The lathe is made up of several machines, parts and tools. While one segment of the machine rotates the object, material or piece to be treated, another part of it makes the cuts, cracks or slots. In industrial terms, this process is known as machining geometrically shaped parts.

Traditional or more basic lathes are propelled thanks to the mobility of the lower and upper extremities of an operator. In this case, human force is responsible for triggering the action of the lathe. In them, basic operations can be carried out after moving the piece, such as cutting, slotting or cracking, among others.

The most advanced models, on the other hand, can be composed of two or more carts, for the execution of tasks with greater precision and diversity in the material. The cars can be programmed according to the purpose that the industry or operator wishes to achieve and can move in different directions.

Diversification of industrial lathes

Industrial lathes are one of those machine tools that various factories or workshops have integrated into the development of common activities in the secondary sector. This equipment is mainly used in the automotive, electrical, computer, dental, wood and plastic industries; in addition to being intended for the production of tools, instruments and other distinctive equipment or intended for these or other areas.

According to the needs of each particular sector, the lathe can have different characteristics, both in its operation and in its components, in order to generate the desired results.

Some important distinctions are presented below:

Most notable branches of turning

| Revolver turning | As in a revolver, this branch of turning is involved in the process of machining various parts. |

| Milling turning | A strong, rotating piece of metal is used, which includes several plates in turn, to make the required mechanized cuts. |

| Copier turning | It is responsible for reproducing an already established pattern. Basically, ?copy? a template to recreate the pieces. |

| Automatic turning | It uses CNC technology (with computerized numerical control) for the production of smaller pieces, classified as small or medium, or for fixing details of required precision. |

Classification of lathe types

| Vertical lathes | These are designed to work correctly with large volume pieces, machined and rotated on a vertical axis. |

| Horizontal lathes | These lathes operate by rotating the workpiece in a horizontal axis. It is a team with an important presence in the industry due to its recognized effectiveness. |

| CNC lathes | Computerized numerical control lathes are the most modern or technological. For its control, numbers, letters and symbols are used and its management is facilitated by software. |

| Automatic turning | It uses CNC technology (with computerized numerical control) for the production of smaller pieces, classified as small or medium, or for fixing details of required precision. |